Overcoming AI Challenges in Vietnam Manufacturing: Insights & Advice from AgentIQ AI

- Publised September, 2025

This blog explores AI barriers with a focus on Vietnam’s unique manufacturing landscape, and shares practical insights to overcome them

Table of Contents

ToggleKey Takeaways

- Global AI Barriers Apply Locally: Vietnam’s manufacturers face universal AI adoption hurdles—skills shortages, fragmented data, and integration issues—costing millions in downtime and missed efficiency gains (e.g., 40% potential efficiency losses due to poor integration).

- Vietnam’s Unique Challenges: SMEs (98% of businesses) struggle with an aging workforce, limited capital, and undocumented expert knowledge, slowing AI adoption in key hubs like Binh Duong and Dong Nai.

- Generic AI Falls Short: Large language models lack factory-specific context, leading to errors, unreliable outputs, and compliance risks, especially with strict ESG regulations.

AI Solutions in Manufacturing Overview

Artificial Intelligence (AI) is transforming manufacturing worldwide, promising faster production, lower costs, and smarter operations. In Vietnam, a manufacturing powerhouse with an 11% projected digital economy growth in 2025 (Innovature Inc., 2025), AI offers immense potential. However, many factories struggle to turn this promise into reality due to hidden challenges like skills shortages, scattered data, and integration issues.

Global AI Challenges in Manufacturing

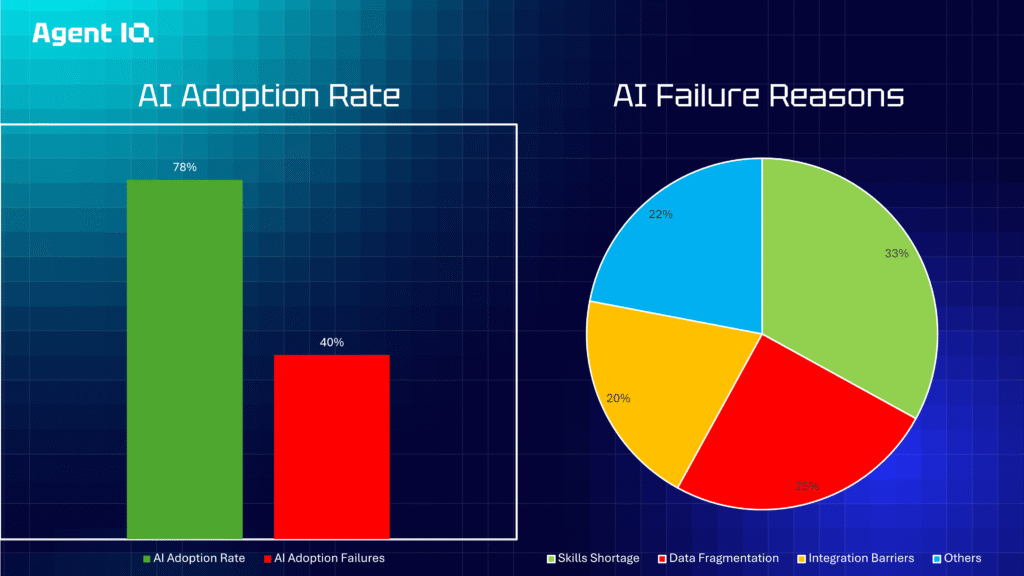

Manufacturers worldwide face three major barriers to AI adoption, as reported in 2025 industry studies. These challenges cost time, money, and competitiveness.

- Skills Shortages: A 2025 Deloitte survey of 600 executives found 40% lack AI-trained staff. Additionally, 20–30% of institutional knowledge is lost yearly as veteran workers retire. This creates delays when expertise is unavailable.

- Data Fragmentation: McKinsey’s 2025 workplace AI report notes 56% of manufacturers struggle with disconnected data in ERP, MES, or SCADA systems. This leads to unreliable AI outputs, slowing decisions and risking errors.

- Integration Barriers: CohnReznick’s in 2025 highlight a trend that 39% of AI projects fail to scale due to poor system integration and lack of leadership support. Without seamless connections, AI remains stuck in pilot mode.

These global challenges highlight a truth: AI’s value depends on capturing knowledge, unifying data, and integrating systems effectively.

Vietnam’s Unique AI Challenges

Vietnam’s manufacturing sector, driven by SMEs (98% of businesses), faces amplified challenges due to its rapid growth and unique context, as stated by Invest Vietnam (Aug 2025). Here are the key barriers:

- Aging Workforce & Skills Gap: Vietnam’s workforce is aging, with many workers less familiar with AI technologies. A 2025 report notes 55% of SMEs lack skilled AI staff, slowing adoption in hubs like Binh Duong and Dong Nai.

- Capital Constraints: SMEs often lack funds for complex AI tools, limiting investment in digital transformation. This creates a gap between ambition and execution.

- Knowledge Retention: Expert knowledge, such as a veteran engineer’s 30 years of insights, is often undocumented. When workers retire, this knowledge is lost, causing inefficiencies and delays.

For example, a factory in Dong Nai may rely on a few expert fors machine troubleshooting, while the majority of new-comers and non-seniors are stuck learning the rope all by themselves. If those experts is unavailable, production stops, costing thousands of dollars daily. Vietnam’s AI usage score (37.6/100, ranked 17th globally shows promise, but underscores the need to address these barriers for an effective & efficient operation.

Why Generic AI Tools may not be the answer?

Generic AI tools, like large language models (often known as LLMs), often fail in manufacturing because they lack context for specific factory needs. They may misinterpret manuals or workflows, leading to errors or delays. For instance, a generic AI might suggest incorrect fixes for a machine breakdown, wasting time. It is true that Generative AI works best in non-technical environment, but in an industry where just a 1% may means profit or loss – we need an expert AI, tailored for Manufacturing only.

Moreover, these tools struggle with:

- Knowledge Gaps: They don’t capture internal expertise, such as a veteran worker’s troubleshooting methods, or your pre-exisiting knowledge within an enterprise.

- Data Issues: Without integration into ERP or SCADA systems, they produce unreliable outputs, not connected to live data – means you lose visibility on your line in real time.

- Governance Risks: Lack of control over data increases compliance risks, especially for SMEs facing strict regulations. With ESG arising as one of the most important certificate for manufacturers, non-transparent data may decrease your scoring.

To succeed, manufacturers need a platform that captures – organizes & curate their knowledge, integrates data seamlessly, and ensures full control. Knowledge is your most important asset, and that is your lasting competitive edge in a fast changing world. AgentIQ AI is your go-to solution for this. Let’s discover more about us.

AgentIQ AI: The Proven Solution

AgentIQ AI, developed by New Ocean IS with over 15 years of experience and trusted by Nestlé, Pepsico, Khatoco Khanh Hoa & Cat Loi Tobacco, is designed to overcome these challenges. It transforms your enterprise knowledge—your most important asset—into secure AI agents that deliver results in under 45 days.

- Captures Knowledge: AgentIQ AI collects and standardizes expert insights, workflows, and real-time data (e.g., from ERP/SCADA). For example, a veteran’s troubleshooting tips are turned into a playbook, ensuring knowledge isn’t lost.

- Unifies Data: It integrates systems for fast, reliable insights, enabling 40% faster decisions and 20–30% higher efficiency.

- Ensures Control: With full data ownership and role-based governance, you decide who accesses knowledge, keeping it secure.

- Scales Easily: Business-friendly tools let managers create agents without coding, while flexible deployment (on-premise or cloud) suits SMEs and large factories.

AgentIQ AI delivers measurable results: 50% faster non-decision work, 15–25% lower operational costs, and 10–15% better production efficiency. For Vietnam’s SMEs, it’s a low-barrier solution to compete globally.

Start Your AI Journey, today!

AI can transform Vietnamese manufacturing, but success requires addressing skills gaps, data fragmentation, and integration challenges. AgentIQ AI, built on your enterprise knowledge, offers a proven path to faster, smarter, and more secure operations.

Ready to see results?

Contact info@agentiqai.ai for a free 2-week Proof of Concept using your data. Unlock AI’s potential in under 45 days.

Your Knowledge, Your Agents, Your Control